Cost efficiency opportunities and continues improvement

We help you identify ways to save costs in your supply chain.

At BrassMasters, we specialize in helping organizations like yours identify cost efficiency opportunities and driving continuous improvement in your supply chain.

We understand the critical importance of optimizing costs to maintain a competitive edge in today’s business landscape. With our expertise in methodologies such as Quick Response Manufacturing (QRM), Value Stream Mapping (VSM), and Standard Working Procedures (SWP), we assist you in uncovering potential savings and implementing strategies that enhance your operational efficiency.

Our team of experts at BrassMasters works closely with your organization to conduct a comprehensive analysis of your supply chain processes. Using methodologies like Value Stream Mapping, we identify areas of waste, bottlenecks, and non-value-added activities that may be impacting your cost efficiency. By employing Quick Response Manufacturing principles, we develop strategies to reduce lead times, improve flow, and enhance overall responsiveness. Through the implementation of Standard Working Procedures, we establish standardized processes, optimize work instructions, and ensure consistency and efficiency across your operations.

Through continuous improvement initiatives, we strive to enhance your supply chain performance on an ongoing basis. At BrassMasters, we believe in embracing methodologies like Lean Manufacturing and Six Sigma to drive process improvements. By applying Lean principles such as 5S, Kaizen, and Kanban, we eliminate waste, streamline processes, and create a culture of continuous improvement.

We also leverage the power of Six Sigma methodologies to identify and eliminate variations, reduce defects, and enhance overall quality.

At BrassMasters, we understand that cost efficiency goes beyond simply cutting expenses. We take a holistic approach, considering various factors such as process optimization, supplier relationships, inventory management, and technology utilization. By employing Value Stream Mapping techniques, we visualize your end-to-end processes and identify opportunities for streamlining and eliminating waste. Through the implementation of Standard Working Procedures, we establish clear guidelines and instructions to ensure consistency, efficiency, and quality in your operations.

Transparency and collaboration are at the core of our approach. At BrassMasters, we work hand-in-hand with your team, fostering open communication and knowledge sharing. We involve key stakeholders throughout the process, ensuring that everyone is aligned with the identified cost efficiency opportunities and improvement initiatives. By empowering your team with the necessary tools, skills, and insights, we enable you to sustain the progress achieved long after our engagement.

With BrassMasters as your partner in cost efficiency and continuous improvement, you can expect tangible results. Our track record speaks for itself, as we have successfully helped numerous organizations optimize their supply chains, achieve significant cost savings, and improve overall performance using methodologies like QRM, VSM, and SWP.

Unlock the full potential of your supply chain and maximize cost efficiency with BrassMasters. Contact us today to learn more about how our expertise in QRM, VSM, and SWP can help you identify savings opportunities and drive continuous improvement. Together, let’s build a leaner, more efficient, and more competitive supply chain that propels your business towards success.

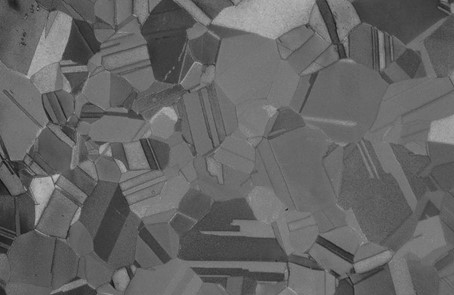

Metallurgy expertise

We help you make informed material choices and optimize product properties

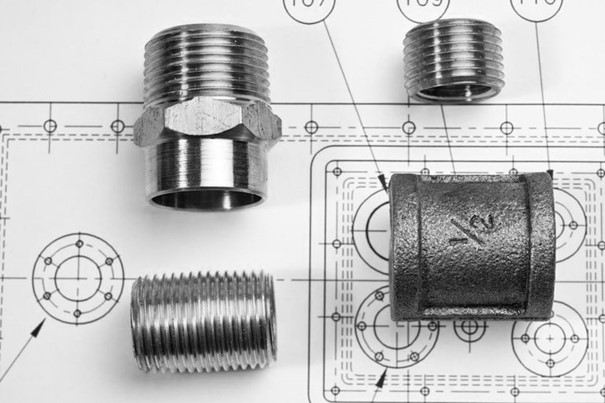

Product placement

We find the right market for your copper-based products, expanding your sales opportunities

Process and product improvements

Our experienced professionals enhance your processes and products for higher quality and efficiency

Quality, Health, Safety, and Environment (QHSE) management

We ensure your operations comply with top standards and regulations

Cost efficiency opportunities and continues improvement

We help you identify ways to save costs in your supply chain

Stakeholder management, advisory support, and end-to-end project delivery

Empowering Your Projects from Concept to Completion.